Laser or Light Amplification By Stimulated Emission of Radiation is a key component in many applications that we use today. Out of hundreds of different uses Laser technology has to offer, one major use is the application of laser as an effective cutting tool. With some fine tuning, Lasers can be used to cut up almost anything, ranging from piercing through high density metal plates used in steel manufacturing, to extremely delicate and high precision requiring LASIK eye surgeries. So, in today’s tutorial, we are going to go over a step by step process on how to design a powerful 1000mW Laser Diode Module Driver circuit Using LM317 Voltage Regulator IC and a Laser diode.

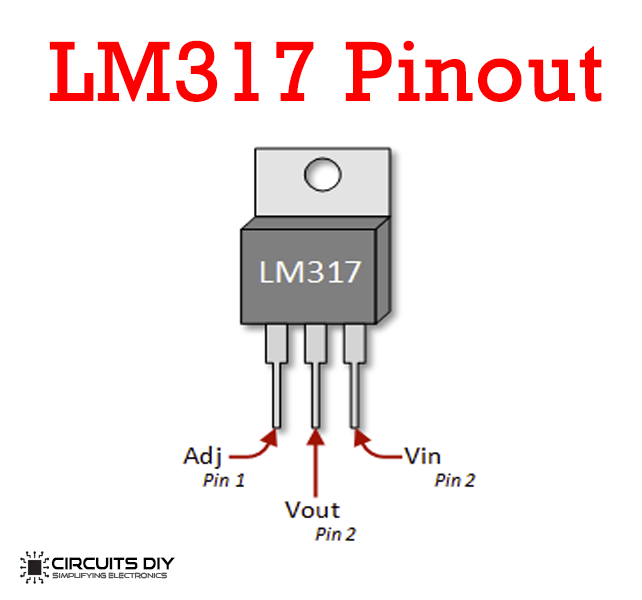

LM317 IC

LM317 is a three-terminal voltage regulator IC, with a high output current value of 1.5A. The LM317 IC has many features such as current limiting, thermal protection, and safe operating area protection. It can also provide a float function for high voltage uses. If we disconnect the adjustable terminal still, LM317T will be helpful in overload protection.

Laser Diode

A Laser diode is a semiconductor device that uses a P-N junction to generate coherent light in which all the waves are at the same frequency and phase. Laser diodes emit a high powered light through a lens in order to minimize the signal loss. They are also called injection laser diodes and, their operation is somewhat similar to that of general LEDs.

Hardware Component

You will need the following parts to build this project

| S.No | Component | Value | Qty |

|---|---|---|---|

| 1) | Voltage Regulator IC | LM317 | 1 |

| 2) | Laser Diode | 445nm, 1.8W | 1 |

| 3) | Metal Laser Diode Module Housing | TO-18 | 1 |

| 3) | Heatsink (optional) | – | 2 |

| 4) | Safety glasses | Rated for 445nm, 1.8W laser | 1 |

| 5) | DC Fan | 12V | 1 |

| 6) | Brass casing (optional) | – | 1 |

| 7) | Resistor | 1.3 Ohm, 1.5W | 1 |

| 8) | Capacitor | 47uF | 1 |

| 9) | Soldering Iron | 45W – 65W | 1 |

| 10) | Soldering Wire with Flux | – | 1 |

| 11) | Toggle Switch | – | 1 |

| 12) | Thermal Compound paste | – | 1 |

| 11) | DC Battery | 12V | 1 |

| 12) | Battery Clip | – | 1 |

| 13) | Veroboard | – | 1 |

| 14) | Jumper Wires | – | As per need |

LM317 Pinout

Useful Steps

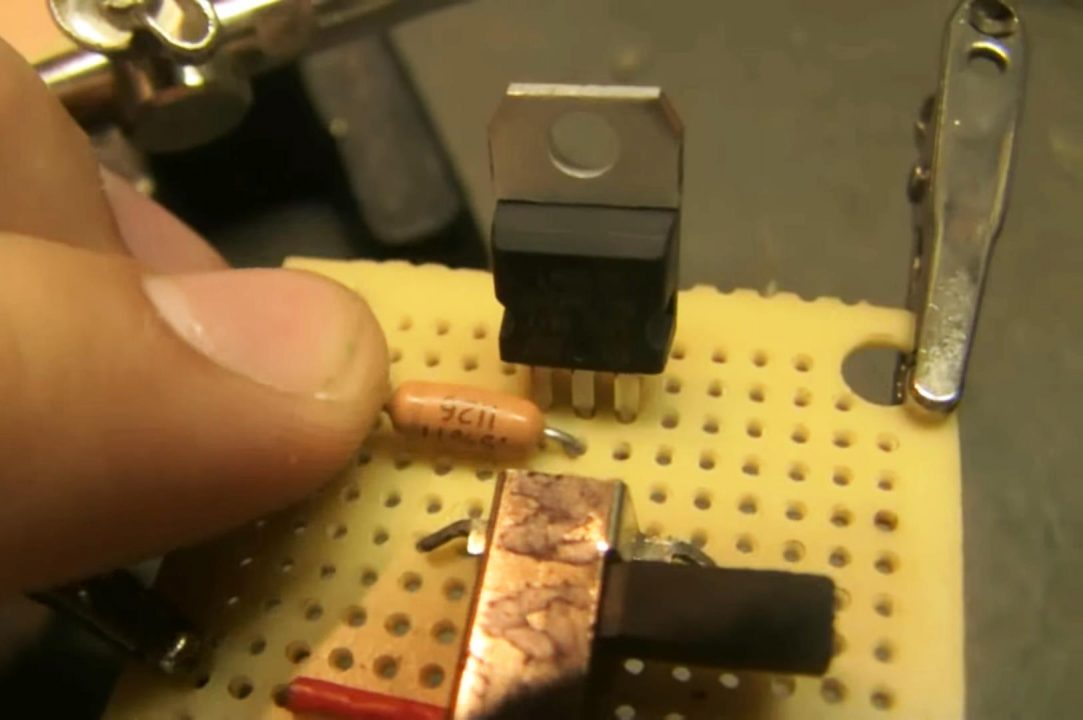

1) Solder the LM317 IC on the Veroboard. After that, solder the toggle switch for the laser diode with the Vcc and GND of the circuit.

2) After that solder the 1.3 Ohms wire wound resistor between the Vout and ADJ pin of the LM317 IC.

3) Solder the +ve pin of the 47uF capacitor with 1.3 Ohm resistor and the -ve pin with the GND of the circuit.

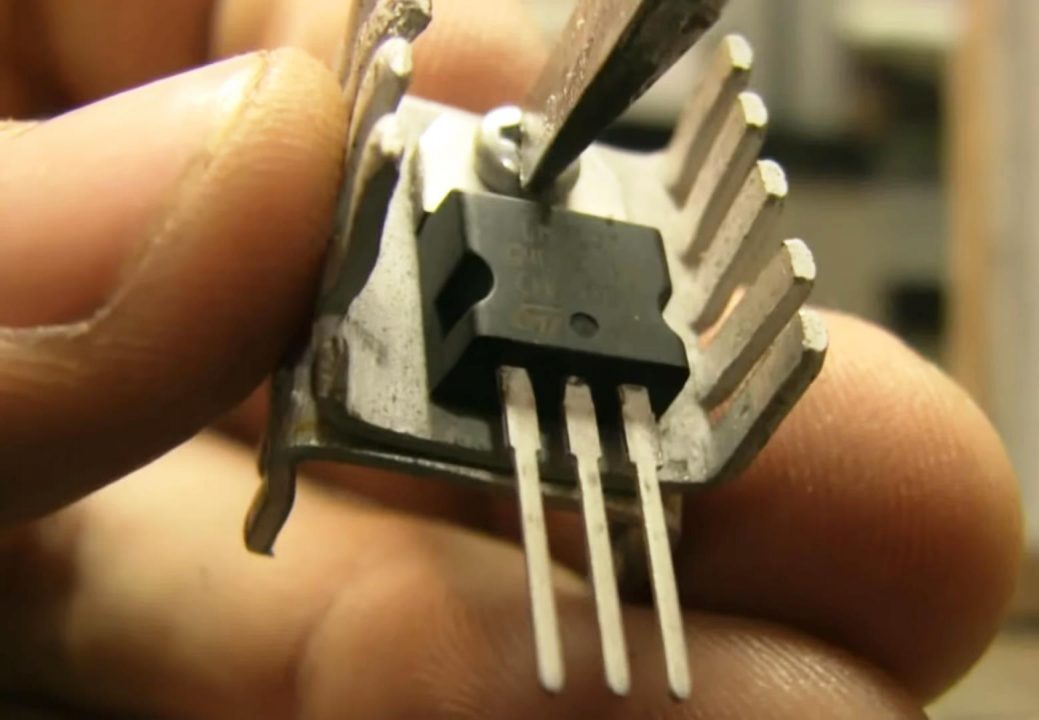

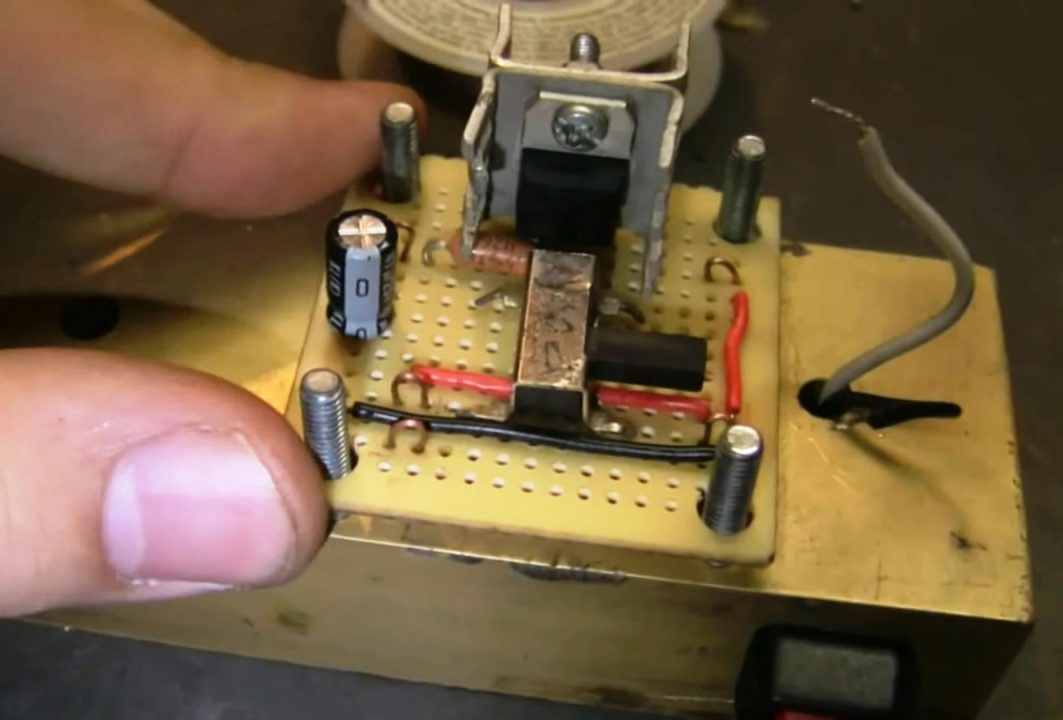

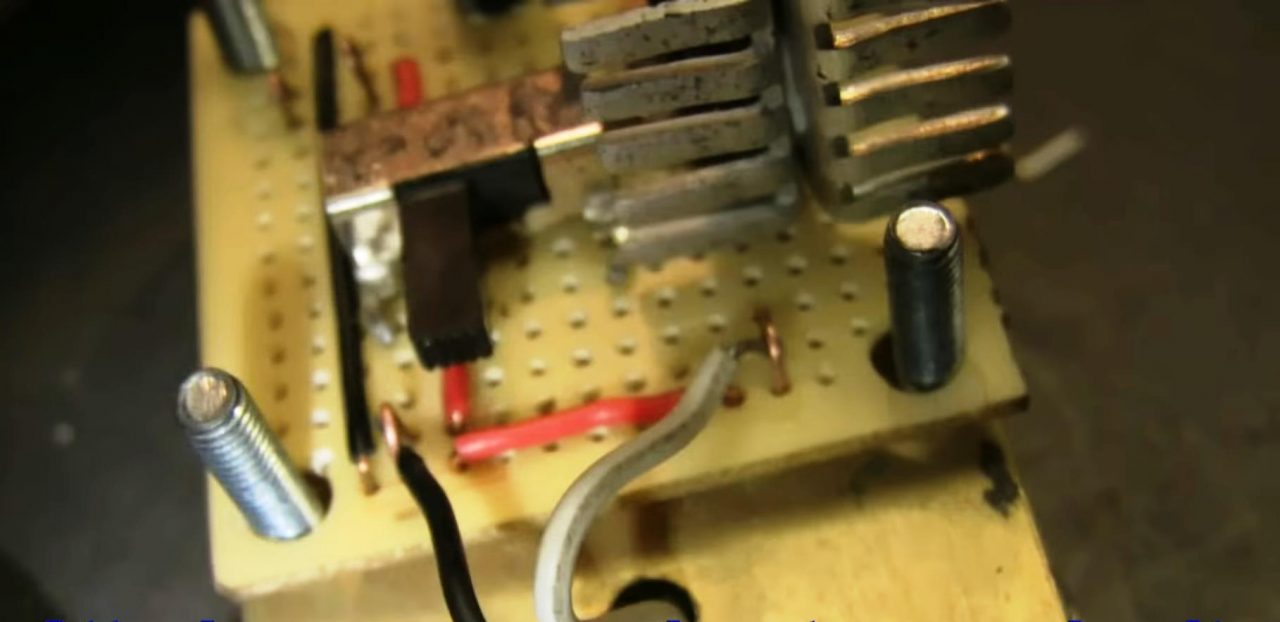

4) Optionally, you can also connect heat sinks with your LM317 IC. For the best cooling effect, use two heatsinks with thermal cooling paste behind the LM317 IC. You can also attach a DC cooling fan on top of the heat sink in order to optimize the cooling process.

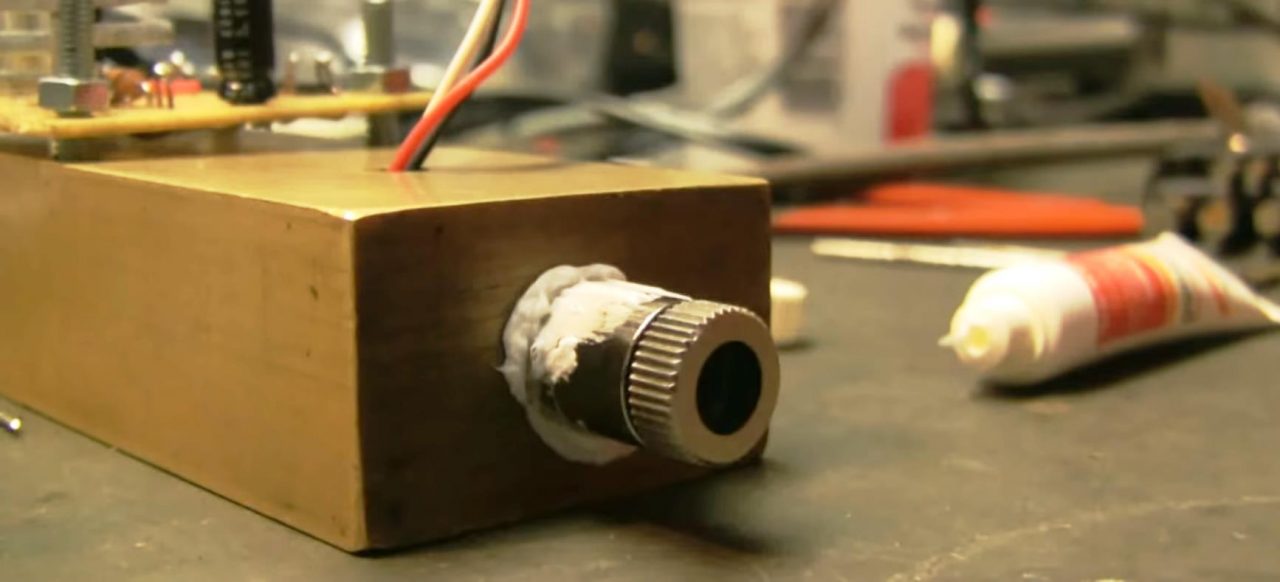

5) After that, drill four holes on the circuit board and secure it with a brass case.

6) Connect the -ve pin of the cacitor with the -ve of the battery and +ve pin of the battery with Vin pin of the LM317 IC.

7) Fit the laser diode within the metal housing. After that, join the +ve of the laser diode with the capacitors -ve pin and -ve with the GND of the circuit. Also, add some thermal paste on the diode housing to keep it cool during operation.

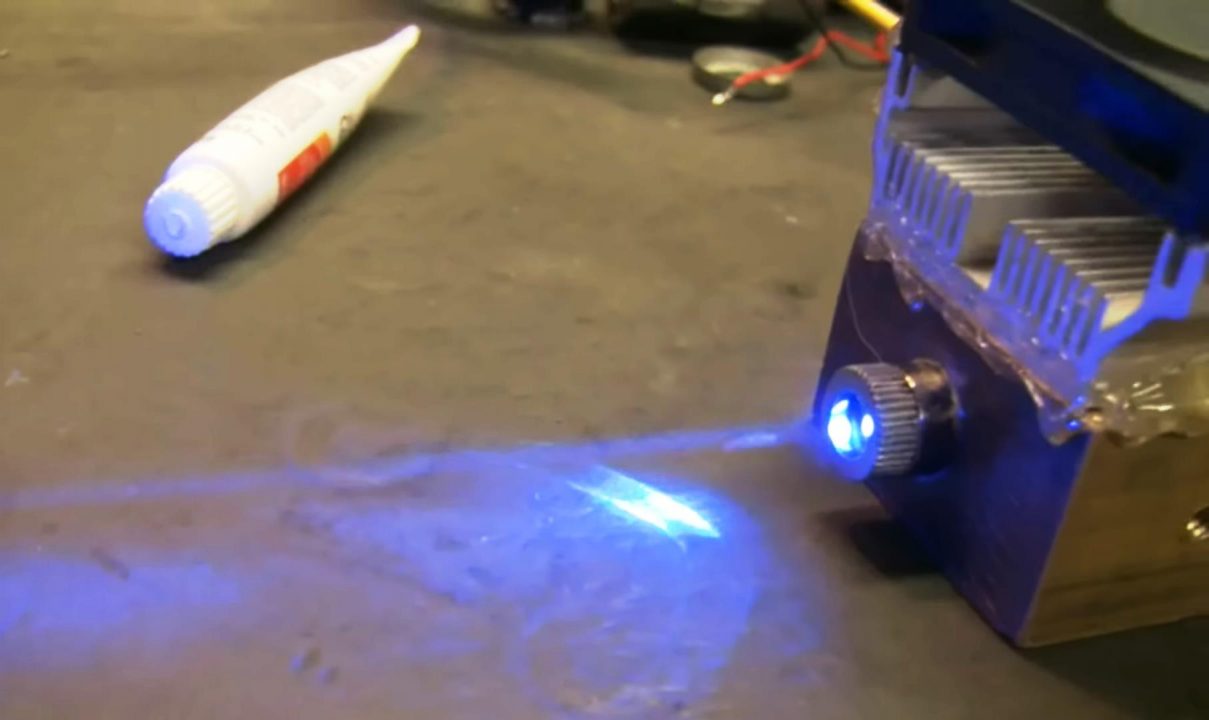

8) Power up and test the circuit.

Working Explanation

The heart of the circuit is an LM317 IC that acts as a current limiter. The circuit is using a 1.3 ohms/1.5W wire wound resistor to adjust the output current. The 10uF electrolytic capacitor smoothes the output of the LM317 IC.

The output wattage from the laser is immensely powerful and can easily crossover the 1000mW threshold. Monitor the temperature of the voltage regulator and the laser diode casing during circuit operation and use thermal compound where necessary. It is not advisable to run the circuit for longer periods of time as it may damage the regulator IC.

Precautions

- DO NOT point the laser at yourself or another person as it may cause serious burns.

- DO NOT point the laser at your eye or of another person/animal. The 1000mW output will render you or them blind instantly.

- ALWAYS Use safety glasses and hand gloves while operating the laser. Also, check if the safety glasses are rated for the wavelength of the laser diode you are using.

- ALWAYS check with the local law enforcement of your area before designing or using powerful lasers as it is considered illegal to design and use high power lasers in most areas.

- DO NOT point the laser at any oncoming traffic as it could lead to a dangerous accident.

Applications

- A laser as a cutting tool is used in a huge number of applications such as Engravers, sheet cutters, laser scissors, etc.

See Also: How To Make An IoT Web Server Using ESP32 WROOM With Arduino IDE | Power Inverter (200W) Using CD4047 Monostable/Astable Multivibrator IC | How To Interface MQ2 Gas Sensor With Arduino Uno | DIY Arduino Project